- Home | Industry Update | China Ends Dependence On Foreign Carbon Fiber As T1100 Enter...

China Ends Dependence on Foreign Carbon Fiber as T1100 Enters Aerospace Production

This is not just about carbon fiber. China went from T300 in 2008 to T1100 in 2025. That is 17 years to close a 30 year gap with Japan.

The Wassenaar export controls pushed them to do it themselves.

India is still importing T300 grade and calling it self reliance. We have no roadmap to T800, forget T1100.

Industry and academia are not talking to each other in India. IITs produce papers. DRDO produces delays. Private sector produces JVs with foreign IP.

No one is funding the 10 year grind to crack a T1000 process.

China did it with coal province researchers and state capital. We are waiting for someone else to hand it over.

This is what real chokepoint crossing looks like.

Carbon fiber goes into COMAC jets, rocket casings, and fighter airframes. China no longer needs Toray for its aerospace supply chain.

India still imports carbon fiber for Tejas composites. One country is building the ladder. The other is renting it.

India has a textiles minister promising carbon fiber by 2025-26 but no lab, no pilot line, no yield data.

Reliance is planning 4000 tons of basic grade by 2026. China just started 200 tons of T1100 aerospace grade with 95% yield. We are not even on the same ladder.

Wassenaar list was supposed to protect the West. Instead it pushed China to build its own supply chain from scratch.

Now they make T1100 for COMAC jets and rocket casings. Export controls only work if the target cannot learn. China can.

China has state labs, state capital, and state demand all working together for 20 years.

India has DRDO, Reliance, and HAL all doing separate things with no roadmap. The question is not can we catch up.

The question is whether anyone in Delhi even knows how far behind we are?

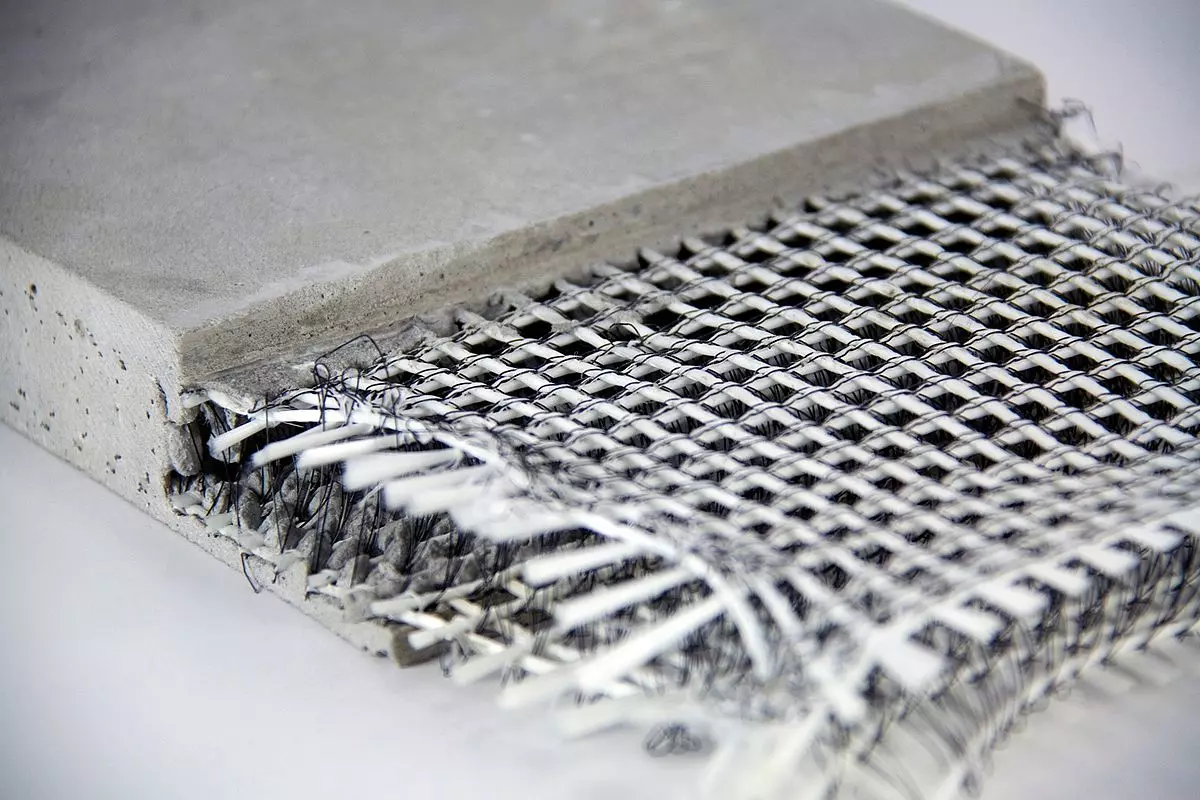

This is about China achieving mass production of T1100-grade carbon fiber - a material so advanced that only Japan's Toray Industries could make it commercially until now.

Why it matters?

T1100 carbon fiber is essentially the strongest, lightest structural material humans can produce at scale.

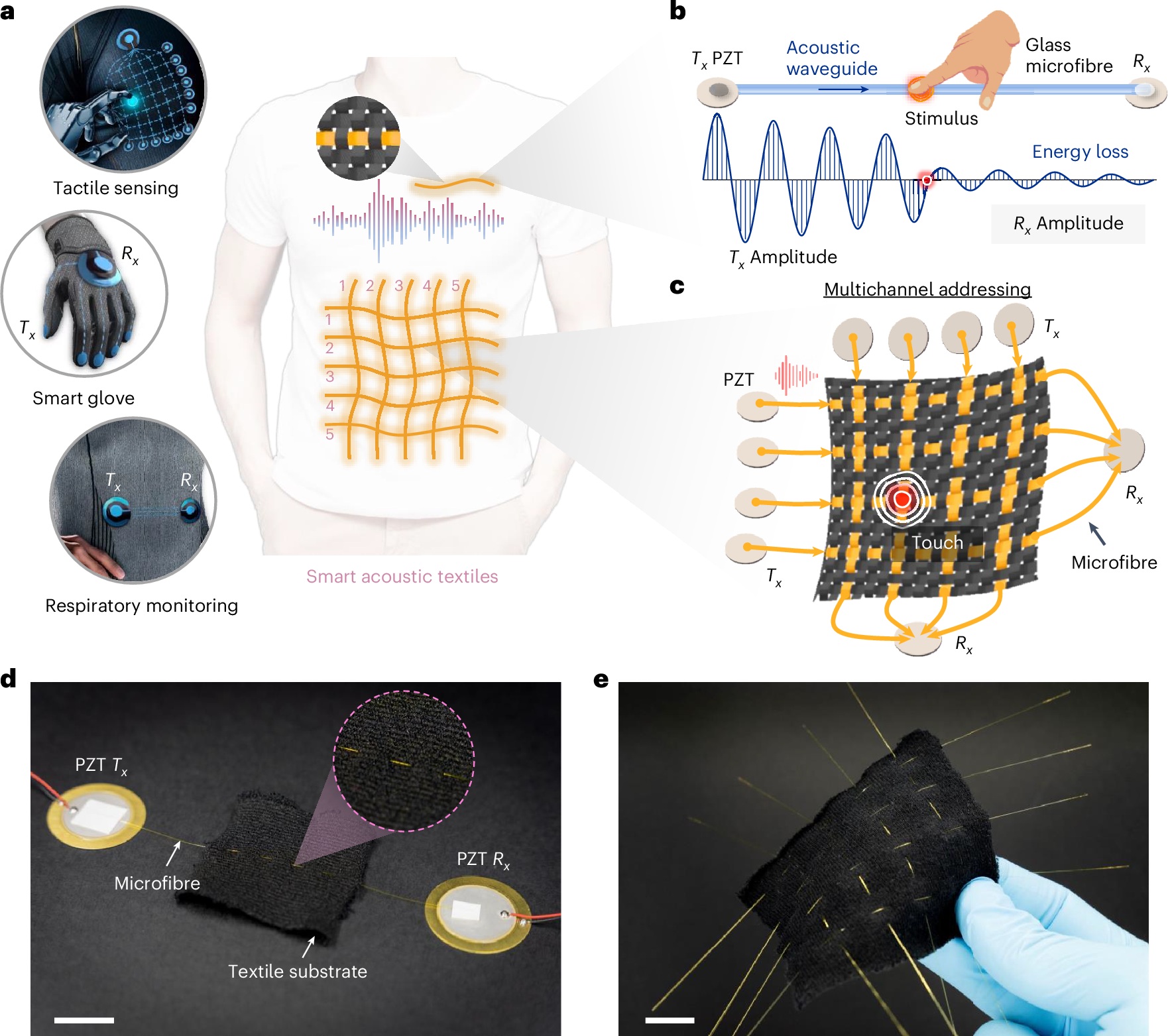

It's critical for fighter jets, satellites, rocket bodies, and next-gen civilian aircraft.

The material is so strategically sensitive that Japan and the US have strict export controls, you simply cannot buy it if you're China.

China has moved from lab samples to factory production. This is the hard part - lots of countries can make small quantities of advanced materials in a lab, but scaling to industrial volumes while maintaining quality is where most fail.

The "valley of death" between lab and factory is littered with promising technologies.

China's aerospace and defense programs are no longer bottlenecked by foreign carbon fiber supply.

Their C919 passenger jet, (until now one Airbus & Boeing have the monopoly) military aircraft programs, and space ambitions all become more achievable without dependency on materials they couldn't import anyway.

It also means Chinese wind turbine blades, pressure vessels, and sporting goods can use domestic high-grade Fiber.

10:03 AM, Feb 04

.webp)

.webp)

Industry Update

Kolkata Set to Become Textile Sourcing Hub as YARNEX and TEXINDIA Return in January 2026...view more

India Textile Industry 2025 Review: How US Tariffs Hit Exports, and the Road to Recovery...view more

Europe’s Textile Sector Alarms as Ultra-Fast Fashion Firms Partner With Postal Operators...view more

Indorama Ventures Pioneers Scalable Bio-Based PET Fibers for a Low-Carbon Textile Future...view more

Carrington Textiles Introduces Defence Stock Range for Faster Access to Military Fabrics...view more

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.png)

.jpg)

.jpg)

.jpg)

1.jpeg)