- Home | Industry Update | Germany Launches ‘wave’ Project To Turn Wool Into High-p...

Germany Launches ‘WAVE’ Project to Turn Wool into High-Performance Textile Insulation Panels

.webp)

A Sustainable Shift in Thermal & Acoustic Innovation

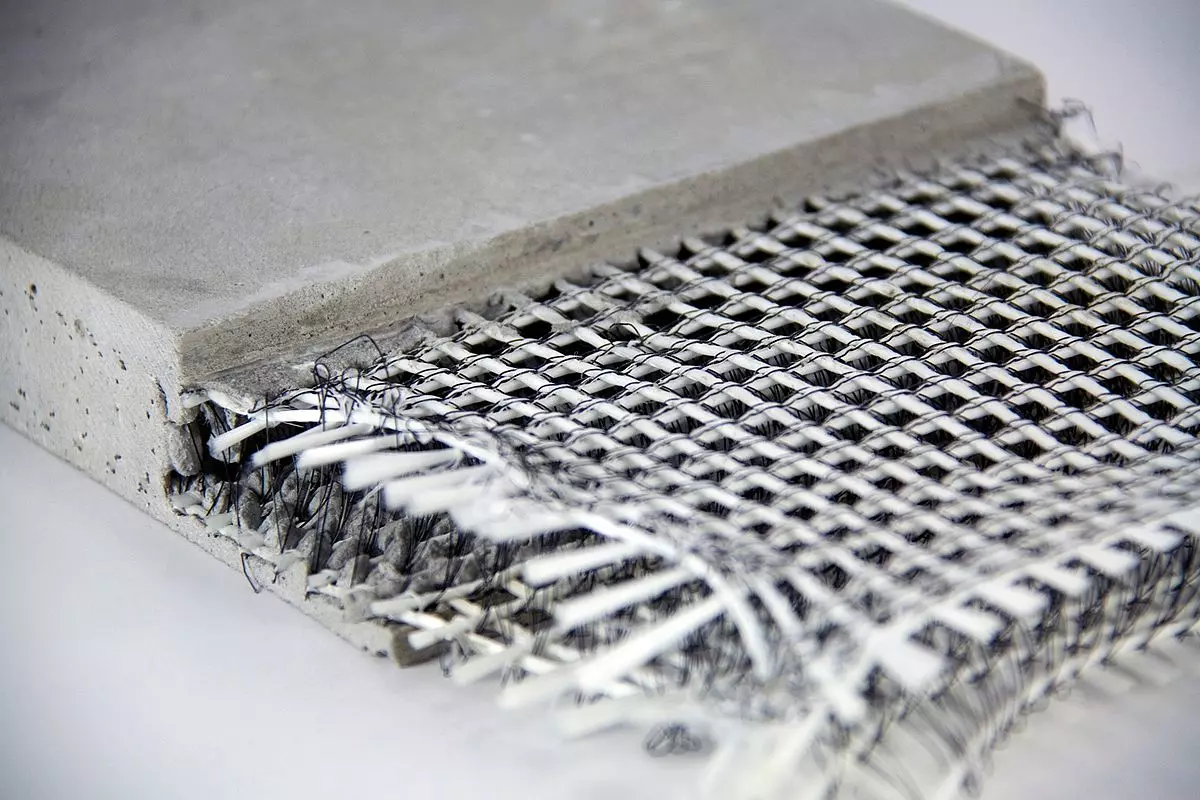

In a decisive step toward greener construction solutions, Hof University of Applied Sciences has launched an ambitious research initiative aimed at redefining how buildings are insulated. The two-year project, titled WAVE (Thermal Insulation and Acoustic Optimisation through the Use of Residual Materials as Fillers in Near-Net-Shape 3D Woven Structures for Textile Panels), focuses on developing textile-based insulation panels using locally sourced wool.

Supported by funding from the German Central Innovation Programme for SMEs (ZIM), the project brings together academic expertise and regional industry partners from Upper Franconia. At its core, WAVE addresses a pressing market demand: insulation materials that are sustainable, recyclable, biodegradable and free from petrochemical components without compromising performance.

Project lead Professor Dr.-Ing. Frank Ficker of the Institute of Materials Science (ifm) describes the initiative as a meaningful intersection of ecological responsibility, material innovation and regional value creation.

Wool Reimagined: From Surplus Fibre to Smart Construction Material

The construction industry has long relied on petrochemical-based insulation products that are difficult to recycle and often environmentally burdensome. WAVE aims to challenge that model by unlocking the untapped potential of regional wool an abundant yet underutilised raw material. Key objectives of the project include:

- Developing fully textile 3D woven panel systems

- Combining thermal insulation and acoustic optimisation in one material

- Eliminating adhesives and critical additives

- Ensuring recyclability or compostability

- Maintaining structural stability and design flexibility

By leveraging advanced weaving and textile engineering techniques, researchers aim to create panels that not only insulate but also enhance indoor acoustics making them suitable for offices, educational institutions and cultural buildings.

Corinna Anzer, deputy project lead, highlights the advantage of textile structures in integrating functionality, stability and aesthetics within a single system opening new pathways for interior construction solutions.

From Laboratory to Market: Strengthening Regional Textile Industry

The WAVE project follows a structured development pathway. Initial laboratory research at the ifm will focus on functional textile structures and innovative filling concepts. The second phase will scale production through collaboration with Möbelstoffweberei Reich e.K., ensuring practical viability and industrial readiness.

By the end of the project, the partners aim to deliver a market-ready prototype with verified acoustic and thermal performance metrics. The initiative also strengthens knowledge exchange between academia and small-to-medium enterprises, reinforcing Upper Franconia’s textile innovation ecosystem.

The project’s origin traces back to discussions at “TextilTreff Oberfranken,” a regional networking event that fostered collaboration between researchers and industry stakeholders demonstrating how innovation often begins with dialogue.

If successful, the WAVE initiative could mark a significant breakthrough: transforming surplus wool into high-value insulation panels that combine sustainability, technology and regional economic impact while signalling a forward-looking direction for Europe’s textile industry.

11:54 AM, Feb 19

Industry Update

Kolkata Set to Become Textile Sourcing Hub as YARNEX and TEXINDIA Return in January 2026...view more

India Textile Industry 2025 Review: How US Tariffs Hit Exports, and the Road to Recovery...view more

Europe’s Textile Sector Alarms as Ultra-Fast Fashion Firms Partner With Postal Operators...view more

Indorama Ventures Pioneers Scalable Bio-Based PET Fibers for a Low-Carbon Textile Future...view more

Carrington Textiles Introduces Defence Stock Range for Faster Access to Military Fabrics...view more

.webp)

.webp)

.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.png)

.jpg)

.jpg)

.jpg)

1.jpeg)